SEOUL, SOUTH KOREA & DORTMUND, GERMANY: MagnaChip Semiconductor Corp., a Korea-based foundry, designer and manufacturer of analog and mixed-signal semiconductor products, and ELMOS Semiconductor AG, a Germany-based designer and manufacturer of analog and mixed-signal semiconductors primarily for the automotive industry, announced that MagnaChip Semiconductor ramped production and started delivery of 0.35um automotive qualified processed wafers to ELMOS.

MagnaChip and ELMOS entered into a cooperative agreement to jointly develop automotive semiconductor process technologies in 2008. As a result of this partnership, both companies successfully developed and qualified 0.35um process technologies targeted at products for the automotive semiconductor market.

These jointly developed process technologies are fully qualified for the demanding conditions and certification requirements of automotive semiconductors. This now provides MagnaChip with a significant process technology advantage and allows ELMOS to procure processed wafers manufactured according to automotive standards from another source apart from its own manufacturing facilities in Germany.

TJ Lee, senior VP and GM, Corporate Engineering and SMS Engineering of MagnaChip Semiconductor, commented: "This is a key step in expanding our specialty technology portfolio into the automotive market segment. Our goal is to continue to manufacture highly differentiated and cost-effective products for our customers. We aim to build strategic relationships with world-class partners through outstanding customer service and delivery of quality products. We are very proud to be associated with an automotive industry leader like ELMOS, a partnership which has allowed MagnaChip's foundry services to enter and serve the fast-growing automotive semiconductor market."

Reinhard Senf, CEO of ELMOS, said: "We are pleased to announce that the successful transfer of our automotive process technology now results in a fruitful supply relationship from MagnaChip Semiconductor to ELMOS. The diligent process transfer and true dedication of MagnaChip Semiconductor to the automotive market are warrantors for excellent quality. ELMOS and our customers will benefit from the enhanced flexibility that ELMOS gains through this additional manufacturing source. We look forward to continue and broaden our cooperation with MagnaChip Semiconductor."

Thursday, June 30, 2011

Avantor completes acquisition of POCH S.A.

PHILLIPSBURG, USA: Avantor Performance Materials has completed its acquisition of POCH S.A. from Kulczyk Holding S.A. Terms of the deal were not disclosed. The POCH acquisition complements Avantor’s strategy of growing into new markets and geographies, both organically and through acquisition. Avantor announced its intent to acquire POCH S.A. in April, 2011.

Avantor, formerly Mallinckrodt Baker, manufactures and markets high-performance chemistries and materials around the world under several well-respected brand names, including the J.T.Baker, Macron, Rankem and Diagnova brands. Avantor products are used in a wide range of industries including biotechnology and pharmaceutical production; electronics and photovoltaic manufacturing; and in research, academic and quality control laboratories. The company is owned by an affiliate of private equity firm New Mountain Capital.

Based in Poland, POCH S.A. manufactures products designed for use in classic and instrumental analysis, filtration and microbiology. POCH S.A. also sells laboratory equipment and laboratory glass. In addition, the company manufactures solvents for liquid and gas chromatography and spectroscopy as well as anhydrous solvents. Its markets include pharmaceuticals; food and feed; chemical and petrochemical; environmental protection and research and analytical chemistry.

“POCH is a perfect fit for Avantor because it strengthens our capabilities in Eastern Europe with its expansive manufacturing presence and distribution facility already in place,” said Avantor president and CEO, Jean-Marc Gilson. “As we formally integrate POCH into our organization, we plan to build upon that strong foundation by enhancing our products, support and services to customers in the region.”

“Working closely with Avantor presents us with a unique opportunity to collaborate on an enriched product portfolio while also leveraging our proven manufacturing and distribution capabilities,” said Jaroslaw Bieszczad, POCH S.A. CEO. “Becoming part of an established global leader also benefits our customers, who will now have access to Avantor’s high-quality product line and global support system.”

Fried, Frank, Harris, Shriver & Jacobson LLP and Wardynski & Partners acted as legal advisors to Avantor and New Mountain Capital.

DC Advisory Partners acted as the sole financial advisor and Clifford Chance as legal advisor to Kulczyk Holding.

Avantor, formerly Mallinckrodt Baker, manufactures and markets high-performance chemistries and materials around the world under several well-respected brand names, including the J.T.Baker, Macron, Rankem and Diagnova brands. Avantor products are used in a wide range of industries including biotechnology and pharmaceutical production; electronics and photovoltaic manufacturing; and in research, academic and quality control laboratories. The company is owned by an affiliate of private equity firm New Mountain Capital.

Based in Poland, POCH S.A. manufactures products designed for use in classic and instrumental analysis, filtration and microbiology. POCH S.A. also sells laboratory equipment and laboratory glass. In addition, the company manufactures solvents for liquid and gas chromatography and spectroscopy as well as anhydrous solvents. Its markets include pharmaceuticals; food and feed; chemical and petrochemical; environmental protection and research and analytical chemistry.

“POCH is a perfect fit for Avantor because it strengthens our capabilities in Eastern Europe with its expansive manufacturing presence and distribution facility already in place,” said Avantor president and CEO, Jean-Marc Gilson. “As we formally integrate POCH into our organization, we plan to build upon that strong foundation by enhancing our products, support and services to customers in the region.”

“Working closely with Avantor presents us with a unique opportunity to collaborate on an enriched product portfolio while also leveraging our proven manufacturing and distribution capabilities,” said Jaroslaw Bieszczad, POCH S.A. CEO. “Becoming part of an established global leader also benefits our customers, who will now have access to Avantor’s high-quality product line and global support system.”

Fried, Frank, Harris, Shriver & Jacobson LLP and Wardynski & Partners acted as legal advisors to Avantor and New Mountain Capital.

DC Advisory Partners acted as the sole financial advisor and Clifford Chance as legal advisor to Kulczyk Holding.

Broadcom premier custom IC program helps Alcatel-Lucent develop industry's first 400Gbps network processor

IRVINE, USA: Broadcom Corp., a global innovation leader in semiconductor solutions for wired and wireless communications, announced that Alcatel-Lucent utilized the Broadcom Premier Custom IC Program to develop and deploy the industry's first 400 gigabit-per-second (Gbps) FP3 Network Processor. By supporting 400Gbps transmission speeds, the new FP3 processor opens new possibilities for bandwidth-intensive services, applications and content, while cutting power consumption by up to 50 percent.

With more than 12 million custom networking ICs shipped, the Broadcom Premier Custom IC program offers a higher level of service and performance than traditional custom ASICs, providing superior execution and faster time-to-market. By leveraging the combination of Broadcom's proven design methodology, vast IP library and more than 100 customized libraries, Alcatel-Lucent achieved its aggressive performance and development schedule requirements.

The exponential increase in design complexity in today's system-on-a-chip (SoC) solutions combined with product differentiation and time-to-market pressures has led OEM manufacturers to rely on Broadcom's Premier Custom IC Program rather than choose a custom ASIC supplier.

Broadcom's Premier Custom IC Program offers one of the most extensive networking, mixed signal, and high speed interface IP portfolios available in the industry, a proven time-tested design methodology, and the ability to create custom libraries. By combining these key elements, Broadcom provides a more reliable path to production, thus avoiding costly multiple chip spins and/or schedule delays.

With more than 12 million custom networking ICs shipped, the Broadcom Premier Custom IC program offers a higher level of service and performance than traditional custom ASICs, providing superior execution and faster time-to-market. By leveraging the combination of Broadcom's proven design methodology, vast IP library and more than 100 customized libraries, Alcatel-Lucent achieved its aggressive performance and development schedule requirements.

The exponential increase in design complexity in today's system-on-a-chip (SoC) solutions combined with product differentiation and time-to-market pressures has led OEM manufacturers to rely on Broadcom's Premier Custom IC Program rather than choose a custom ASIC supplier.

Broadcom's Premier Custom IC Program offers one of the most extensive networking, mixed signal, and high speed interface IP portfolios available in the industry, a proven time-tested design methodology, and the ability to create custom libraries. By combining these key elements, Broadcom provides a more reliable path to production, thus avoiding costly multiple chip spins and/or schedule delays.

Instrumentation amplifier combines precision, power efficiency and value for battery-powered medical, instrumentation and consumer devices

NORWOOD, USA: Providing a unique combination of precision, low power and value, Analog Devices Inc. (ADI) introduced the AD8420 micropower, wide-supply-range instrumentation amplifier -- the newest addition to its award-winning instrumentation amplifier product line.

The AD8420 features a high CMRR (common-mode rejection ratio) of 100 dB while consuming 75 uA of power, which provides designers with improved signal quality and longer battery life compared to competitive offerings. The amplifier’s high CMRR makes it well suited for bridge amplifiers, pressure sensing and similar uses, allowing designers to greatly improve signal quality and overall system performance in portable and battery-powered precision signal healthcare and instrumentation applications such as infusion pumps, remote and handheld metering equipment and smart phones.

The AD8420 has excellent dc performance with 200 uV of input offset and 1 uV/°C of offset drift, with improved performance available in the advanced grade AD8420B model. The AD8420 supports rail-to-rail operation on the output with a wide input-voltage range that allows it to amplify signals below supply ground. The gain (1 to 1000) is set by the ratio of two external resistors, providing better gain accuracy over temperature.

The AD8420 features a wide 2.7 V to 36 V single and +/-18 V dual-power supply range and ships in a compact MSOP-8 package. This blend of performance, power, and small size is available for 89 cents in 1,000-unit volumes.

The AD8420 features a high CMRR (common-mode rejection ratio) of 100 dB while consuming 75 uA of power, which provides designers with improved signal quality and longer battery life compared to competitive offerings. The amplifier’s high CMRR makes it well suited for bridge amplifiers, pressure sensing and similar uses, allowing designers to greatly improve signal quality and overall system performance in portable and battery-powered precision signal healthcare and instrumentation applications such as infusion pumps, remote and handheld metering equipment and smart phones.

The AD8420 has excellent dc performance with 200 uV of input offset and 1 uV/°C of offset drift, with improved performance available in the advanced grade AD8420B model. The AD8420 supports rail-to-rail operation on the output with a wide input-voltage range that allows it to amplify signals below supply ground. The gain (1 to 1000) is set by the ratio of two external resistors, providing better gain accuracy over temperature.

The AD8420 features a wide 2.7 V to 36 V single and +/-18 V dual-power supply range and ships in a compact MSOP-8 package. This blend of performance, power, and small size is available for 89 cents in 1,000-unit volumes.

Temporary bonding equipment market will see 5x growth in value 2011-2016

DUBLIN, IRELAND: Research and Markets has announced the addition of the "Thin Wafer Manufacturing Equipment & Materials Markets" report to its offering.

Why thin wafers will require special handling processes and technologies

Many consumer applications will require the need for ultra-thin semiconductor wafers (down to 50m). But as wafer thickness decreases from the traditional 500m to 100m and below, manufacturing challenges arise. Indeed, ultra-thin wafers are less stable and more vulnerable to stresses, and die can be prone to breaking and warping not only during grinding but also at subsequent processing steps.

To address these challenges, as chip thickness is reduced, new processes including temporary bonding technologies will be required for handling such fragile wafers, specifically to support the wafer during backgrinding and subsequent post-thinning processes.

As tapes can no longer be used for ultra-thin wafers (main reasons are the non-uniformity of the tapes, adhesion and extreme flexibility), new wafer handling technologies have to be developed. We are at the very start of an impressive market growth for temporary bonding technology.

The Thin Wafer Manufacturing Equipment & Materials Market report is the first Yole report to describe the markets, applications and technologies for thin wafer manufacturing: our scope covers temporary bonding markets, applications, descriptions and trends for wafer thinning and dicing. This report also includes a market analysis on temporary bonding materials (wax, glue, tapes, carrier wafers) associated with the temporary bonding technology.

Temporary bonding market will undergo 5X market growth over 2011-16

Temporary bonding is definitively a multiple-applications market. This is why the market is expected to boom. We estimate the total number of wafers requiring temporary wafer bonding will be more than 35M by 2016 (all wafer sizes).

Main applications driving temporary bonding are Advanced Packaging applications (TSV, interposers and Fan Out WLP), Power Devices (IGBTs), RF Devices and LEDs.

By 2016, we evaluate the wafer temporary bonding (WTB) market equipment value for wafer and panels to be $300 million by 2016.

Why thin wafers will require special handling processes and technologies

Many consumer applications will require the need for ultra-thin semiconductor wafers (down to 50m). But as wafer thickness decreases from the traditional 500m to 100m and below, manufacturing challenges arise. Indeed, ultra-thin wafers are less stable and more vulnerable to stresses, and die can be prone to breaking and warping not only during grinding but also at subsequent processing steps.

To address these challenges, as chip thickness is reduced, new processes including temporary bonding technologies will be required for handling such fragile wafers, specifically to support the wafer during backgrinding and subsequent post-thinning processes.

As tapes can no longer be used for ultra-thin wafers (main reasons are the non-uniformity of the tapes, adhesion and extreme flexibility), new wafer handling technologies have to be developed. We are at the very start of an impressive market growth for temporary bonding technology.

The Thin Wafer Manufacturing Equipment & Materials Market report is the first Yole report to describe the markets, applications and technologies for thin wafer manufacturing: our scope covers temporary bonding markets, applications, descriptions and trends for wafer thinning and dicing. This report also includes a market analysis on temporary bonding materials (wax, glue, tapes, carrier wafers) associated with the temporary bonding technology.

Temporary bonding market will undergo 5X market growth over 2011-16

Temporary bonding is definitively a multiple-applications market. This is why the market is expected to boom. We estimate the total number of wafers requiring temporary wafer bonding will be more than 35M by 2016 (all wafer sizes).

Main applications driving temporary bonding are Advanced Packaging applications (TSV, interposers and Fan Out WLP), Power Devices (IGBTs), RF Devices and LEDs.

By 2016, we evaluate the wafer temporary bonding (WTB) market equipment value for wafer and panels to be $300 million by 2016.

Praxair China supplies gases to Hua Li Microelectronics

SHANGHAI, CHINA: Praxair China has begun supplying compressed dry air, ultra-high-purity oxygen, nitrogen, argon, hydrogen and helium to Shanghai Hua Li Microelectronics Corp.'s 12-inch integrated-circuit chips production line.

Hua Li is a state-owned company engaged in the production of advanced integrated circuits. Zhangjiang High-Tech Park of Shanghai is one of the top high-tech parks in China and Praxair is the leading gas supplier in the park.

The semiconductor integrated circuit industry has been defined as a national strategic and fundamental industry in China since the 1990s. The Chinese government planned a number of national priority projects in order to catch up with world-class integrated circuit technology.

“Praxair has been participating actively in the dramatic growth of China’s integrated circuit industry, bringing value-added and energy-efficient solutions to our customers,” said Minda Ho, president of Praxair China.

Hua Li is a state-owned company engaged in the production of advanced integrated circuits. Zhangjiang High-Tech Park of Shanghai is one of the top high-tech parks in China and Praxair is the leading gas supplier in the park.

The semiconductor integrated circuit industry has been defined as a national strategic and fundamental industry in China since the 1990s. The Chinese government planned a number of national priority projects in order to catch up with world-class integrated circuit technology.

“Praxair has been participating actively in the dramatic growth of China’s integrated circuit industry, bringing value-added and energy-efficient solutions to our customers,” said Minda Ho, president of Praxair China.

Zarlink first to deliver IEEE 1588 enabled synchronous Ethernet timing devices

OTTAWA, CANADA: Zarlink Semiconductor has introduced new single-chip timing products capable of delivering the complete synchronization solution required by new wireless technologies, such as Long Term Evolution (LTE).

"Our new timing products are the industry's first single-chip IEEE 1588 enabled SyncE PLL devices," said Louise Gaulin, vice president of Zarlink's Timing and Synchronization product group.

"Our complete approach provides carriers with well established synchronization from SyncE, together with time alignment provided by IEEE 1588. This approach is critically important for wireless operators as they plan a cost-effective migration to packet-based backhaul to support the huge increase in multimedia traffic generated by smartphones and tablets. These new solutions are a key addition to our product portfolio, and are winning designs with customers that will help drive continuing revenue growth for our timing business."

According to Cisco System's recently issued Visual Networking Index forecast, there will be more than 15 billion network connected devices by 2015. Carriers are now strategically investing in packet networks to connect cell sites and the network backbone to help lower operating expenses and meet bandwidth demands of new multimedia traffic created by mobile Internet devices.

Zarlink's packet timing products are designed into wireless base stations, radio network controllers, DSLAM, PON, aggregation and transmission equipment, and routers to ensure network synchronization for multimedia applications now being delivered over packet networks.

Wireless network operators can use both SyncE and IEEE 1588 technologies simultaneously to meet strict performance requirements in 3G and 4G networks. In these applications, SyncE delivers highly accurate and stable frequency references using the physical Ethernet connections. In combination with this, IEEE 1588 distributes time of day and time alignment functionality.

Zarlink's new ZL30342, ZL30343 and ZL30347 IEEE 1588 enabled SyncE devices deliver the required synchronization in a small form factor package. In comparison, competing approaches require external components to generate a reliable frequency reference or rely on expensive GPS systems to provide time of day information.

Key performance features for this new family of products include:

* Single-chip low bandwidth PLLs with very low jitter synthesizers.

* Enables seamless migration path from SyncE to 1588 enabled SyncE.

* Scalable solutions that support external time stamping functionality.

Zarink's IEEE 1588 enabled SyncE devices are now in full production.

"Our new timing products are the industry's first single-chip IEEE 1588 enabled SyncE PLL devices," said Louise Gaulin, vice president of Zarlink's Timing and Synchronization product group.

"Our complete approach provides carriers with well established synchronization from SyncE, together with time alignment provided by IEEE 1588. This approach is critically important for wireless operators as they plan a cost-effective migration to packet-based backhaul to support the huge increase in multimedia traffic generated by smartphones and tablets. These new solutions are a key addition to our product portfolio, and are winning designs with customers that will help drive continuing revenue growth for our timing business."

According to Cisco System's recently issued Visual Networking Index forecast, there will be more than 15 billion network connected devices by 2015. Carriers are now strategically investing in packet networks to connect cell sites and the network backbone to help lower operating expenses and meet bandwidth demands of new multimedia traffic created by mobile Internet devices.

Zarlink's packet timing products are designed into wireless base stations, radio network controllers, DSLAM, PON, aggregation and transmission equipment, and routers to ensure network synchronization for multimedia applications now being delivered over packet networks.

Wireless network operators can use both SyncE and IEEE 1588 technologies simultaneously to meet strict performance requirements in 3G and 4G networks. In these applications, SyncE delivers highly accurate and stable frequency references using the physical Ethernet connections. In combination with this, IEEE 1588 distributes time of day and time alignment functionality.

Zarlink's new ZL30342, ZL30343 and ZL30347 IEEE 1588 enabled SyncE devices deliver the required synchronization in a small form factor package. In comparison, competing approaches require external components to generate a reliable frequency reference or rely on expensive GPS systems to provide time of day information.

Key performance features for this new family of products include:

* Single-chip low bandwidth PLLs with very low jitter synthesizers.

* Enables seamless migration path from SyncE to 1588 enabled SyncE.

* Scalable solutions that support external time stamping functionality.

Zarink's IEEE 1588 enabled SyncE devices are now in full production.

Fujitsu intros new 32-bit MCUs with optimal features for highly efficient electric and hybrid vehicle motor control

SUNNYVALE, USA: Fujitsu Semiconductor America (FSA) introduced a series of new 32-bit microcontrollers (MCUs) that combine excellent performance with a wide range of peripheral functions to enable optimal, high-speed and highly efficient 3-phase inverter motor control in electric (EV) and hybrid vehicles (HV).

The new MB91580 series is part of the FR family of 32-bit RISC architecture microcontrollers, which incorporate embedded Flash memory and feature optimized, high-performance peripherals for EV and HV 3-phase inverter motor control. Applications include EV/HV motor and electric generator control, as well as generic, high-performance, electric motor control.

Highly efficient loopback control is achieved by using a high-speed, dedicated 12-bit A/D converter and Resolver-to-Digital Converter (RDC). Dedicated hardware generates the required motor control parameters (such as the electrical angle's sine and cosine values) to accurately detect motor current and position at high speeds, enabling precise motor control waveform generation.

The FR81S CPU uses the latest and most advanced FR core to deliver 160DMIPS high-performance calculating power. An IEEE-754-compliant Floating Point Unit enables the MCU to process vector conversion and PID control calculations rapidly, using data from the 12-bit A/D converter and RDC.

The resulting solution delivers highly optimized, real-time controllability for EV and HV motors with fast and efficient loopback operation, and the best torque control possible. This level of integration and performance enables system designers to reduce overall motor and motor-control unit costs significantly.

The three members in the series are the MB91F585 (with 576 KB Flash and 48 KB RAM); the MB91F586 (with 832 KB Flash and 64 KB RAM); and the MB91F587 (with 1088 KB Flash and 96 KB RAM).

"The MB91580 series is an ideal design choice for electric and hybrid vehicles because it is designed specifically to support motor control requirements," said Akio Nezu, senior manager for marketing, Fujitsu Semiconductor America. "These microcontrollers use a dedicated embedded resolver sensor interface to control the three-phase inverter, resulting in optimal motor controllability. This enables the system designer to achieve higher performance while lowering the system cost."

The new MCUs, which are available now, come in 144-pin quad flat packages. Sample pricing starts at $25 each.

The new MB91580 series is part of the FR family of 32-bit RISC architecture microcontrollers, which incorporate embedded Flash memory and feature optimized, high-performance peripherals for EV and HV 3-phase inverter motor control. Applications include EV/HV motor and electric generator control, as well as generic, high-performance, electric motor control.

Highly efficient loopback control is achieved by using a high-speed, dedicated 12-bit A/D converter and Resolver-to-Digital Converter (RDC). Dedicated hardware generates the required motor control parameters (such as the electrical angle's sine and cosine values) to accurately detect motor current and position at high speeds, enabling precise motor control waveform generation.

The FR81S CPU uses the latest and most advanced FR core to deliver 160DMIPS high-performance calculating power. An IEEE-754-compliant Floating Point Unit enables the MCU to process vector conversion and PID control calculations rapidly, using data from the 12-bit A/D converter and RDC.

The resulting solution delivers highly optimized, real-time controllability for EV and HV motors with fast and efficient loopback operation, and the best torque control possible. This level of integration and performance enables system designers to reduce overall motor and motor-control unit costs significantly.

The three members in the series are the MB91F585 (with 576 KB Flash and 48 KB RAM); the MB91F586 (with 832 KB Flash and 64 KB RAM); and the MB91F587 (with 1088 KB Flash and 96 KB RAM).

"The MB91580 series is an ideal design choice for electric and hybrid vehicles because it is designed specifically to support motor control requirements," said Akio Nezu, senior manager for marketing, Fujitsu Semiconductor America. "These microcontrollers use a dedicated embedded resolver sensor interface to control the three-phase inverter, resulting in optimal motor controllability. This enables the system designer to achieve higher performance while lowering the system cost."

The new MCUs, which are available now, come in 144-pin quad flat packages. Sample pricing starts at $25 each.

Wednesday, June 29, 2011

OmniVision to acquire wafer-level lens manufacturing operation

SANTA CLARA, USA: OmniVision Technologies Inc., a leading developer of advanced digital imaging solutions, has entered into an agreement with VisEra Technologies Co. Ltd, or VisEra, OmniVision's joint venture with Taiwan Semiconductor Manufacturing Co. Ltd, or TSMC, to acquire from VisEra its wafer-level lens production operations. OmniVision currently outsources the wafer-level lens production and assembly processes associated with its CameraCube technology to VisEra.

The cash consideration for the operations is $45 million. OmniVision anticipates that the parties will close the transaction in the second quarter of its fiscal year 2012.

"We believe that our CameraCube technology represents one area where we can extend our market leadership while increasing the content that we sell into each consumer device," said Shaw Hong, CEO of OmniVision Technologies.

"Historically, sensor and lens manufacturing have been separate endeavors in which the components come together at the modular assembly stage. Our CameraCube technology enables us to design our sensors and accompanying lens elements as an integrated unit that creates a reflowable, monolithic image sensor device. This transaction will enable us to further streamline the production process, consolidate the supply chain, expand production capacity, and reduce the cost to meet customers' growing demand for our CameraCube products."

The cash consideration for the operations is $45 million. OmniVision anticipates that the parties will close the transaction in the second quarter of its fiscal year 2012.

"We believe that our CameraCube technology represents one area where we can extend our market leadership while increasing the content that we sell into each consumer device," said Shaw Hong, CEO of OmniVision Technologies.

"Historically, sensor and lens manufacturing have been separate endeavors in which the components come together at the modular assembly stage. Our CameraCube technology enables us to design our sensors and accompanying lens elements as an integrated unit that creates a reflowable, monolithic image sensor device. This transaction will enable us to further streamline the production process, consolidate the supply chain, expand production capacity, and reduce the cost to meet customers' growing demand for our CameraCube products."

Intel navigates Sandy Bridge recall without a scratch, expands MPU share in Q1

EL SEGUNDO, USA: Despite a design problem that forced a large-scale chipset recall, Intel Corp. in the first quarter managed to pad its dominant position in the global microprocessor business, according to new IHS iSuppli research.

Intel during the first three months of 2011 accounted for 82.6 percent of global microprocessor revenue, up 1.6 points of share from the 81 percent it held in the fourth quarter of 2010. On a year-over-year basis, Intel gained 2.0 percentage points.

The figure presents the IHS ranking of leading microprocessor suppliers in the first quarter of 2011. The market share numbers presented in the tables and this release include revenue for the entire global microprocessor market, including X86, RISC, and other types of general-purpose microprocessors; the data is not limited to the X86 type chips used in the PC market. Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.

Intel in the first quarter discovered an error in the serial ATA controller in its core-logic chipset that supports the company’s Core Sandy Bridge microprocessors. The company said it would recall and replace about 8 million chipsets.

While such a major recall would represent a major setback for most companies, for giant Intel, it didn’t even cause a scratch.

“Intel moved quickly to identify and correct the Sandy Bridge chipset issue during the first quarter,” said Matthew Wilkins, principal analyst, compute platforms, for IHS. “The fact that the company achieved a 25 percent increase in revenue in the first quarter of 2011 compared to the same period in 2010 shows that its chipset concern did not really affect the company to a significant degree. This serves as a testament to Intel’s capability to react to a potential crisis with speed and agility. Intel’s handling of the issue on both the public relations and business fronts stands in stark contrast to other recent examples of big companies facing major product quality challenges.”

While Intel continued to gain, chief Intel rival Advanced Micro Devices Inc. (AMD) saw its share dwindle further. AMD accounted for 10.1 percent of global microprocessor revenue in the first quarter of 2011, down from 10.9 percent in the fourth quarter of 2010, and down from 11.8 percent in the first quarter of 2010.

Despite its decline, both AMD and Intel continued to increase their collective domination of the microprocessor market, with the two companies holding a combined 92.7 percent share of revenue in the first quarter of 2011, up from 92.4 percent in the first quarter of 2010. This represents good news for the two dominant players, given that the worldwide microprocessor market expanded by about 20 percent in the first quarter of 2011 compared to the same period a year earlier.

While Intel continued to ride high in the first quarter, the company this year will face a challenge from the continued market advances of the media tablet.

Although Intel’s sales of its Atom microprocessor for netbook PCs rose in the first quarter, tablets will cut down shipments of netbook PCs this year. Media tablets, most notably Apple Inc.’s iPad, don’t employ dedicated microprocessors like Atom, instead using integrated chips that include processor cores.

Source: IHS iSuppli, USA.

Intel during the first three months of 2011 accounted for 82.6 percent of global microprocessor revenue, up 1.6 points of share from the 81 percent it held in the fourth quarter of 2010. On a year-over-year basis, Intel gained 2.0 percentage points.

The figure presents the IHS ranking of leading microprocessor suppliers in the first quarter of 2011. The market share numbers presented in the tables and this release include revenue for the entire global microprocessor market, including X86, RISC, and other types of general-purpose microprocessors; the data is not limited to the X86 type chips used in the PC market.

Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.Intel in the first quarter discovered an error in the serial ATA controller in its core-logic chipset that supports the company’s Core Sandy Bridge microprocessors. The company said it would recall and replace about 8 million chipsets.

While such a major recall would represent a major setback for most companies, for giant Intel, it didn’t even cause a scratch.

“Intel moved quickly to identify and correct the Sandy Bridge chipset issue during the first quarter,” said Matthew Wilkins, principal analyst, compute platforms, for IHS. “The fact that the company achieved a 25 percent increase in revenue in the first quarter of 2011 compared to the same period in 2010 shows that its chipset concern did not really affect the company to a significant degree. This serves as a testament to Intel’s capability to react to a potential crisis with speed and agility. Intel’s handling of the issue on both the public relations and business fronts stands in stark contrast to other recent examples of big companies facing major product quality challenges.”

While Intel continued to gain, chief Intel rival Advanced Micro Devices Inc. (AMD) saw its share dwindle further. AMD accounted for 10.1 percent of global microprocessor revenue in the first quarter of 2011, down from 10.9 percent in the fourth quarter of 2010, and down from 11.8 percent in the first quarter of 2010.

Despite its decline, both AMD and Intel continued to increase their collective domination of the microprocessor market, with the two companies holding a combined 92.7 percent share of revenue in the first quarter of 2011, up from 92.4 percent in the first quarter of 2010. This represents good news for the two dominant players, given that the worldwide microprocessor market expanded by about 20 percent in the first quarter of 2011 compared to the same period a year earlier.

While Intel continued to ride high in the first quarter, the company this year will face a challenge from the continued market advances of the media tablet.

Although Intel’s sales of its Atom microprocessor for netbook PCs rose in the first quarter, tablets will cut down shipments of netbook PCs this year. Media tablets, most notably Apple Inc.’s iPad, don’t employ dedicated microprocessors like Atom, instead using integrated chips that include processor cores.

Source: IHS iSuppli, USA.

Syntricity delivers dataConductor 7.0

SAN DIEGO, USA: Syntricity Inc. announced the release of dataConductor 7.0, the latest version of its enterprise yield management software. dataConductor 7.0 enables customers to manage large datasets, quickly identify and address unusual results, and share their results as well as methods. Available immediately, dataConductor 7.0 is available through dataConductor.com, a software-as-a-service (SaaS) offering, or as an enterprise installation.

“In dataConductor 7.0, our new user interface helps beginners and experts alike get more out of their analysis sessions. And now, customers can easily take best practices that they’ve implemented and turn them into standardized templates for their engineers, providing a solid foundation for various types of analysis,” said Steven Griffith, CEO and co-founder of Syntricity. “With dataConductor 7.0, we continue to deliver solutions that help our customers develop the next generation of semiconductor products.”

Highlights of dataConductor 7.0 include:

* knowledge sharing through user-configured/shareable templates,

* multi-threaded data loading and statistical analysis,

* new analysis capabilities in RaCR, the rapid characterization and root cause analysis application for dataConductor,

* operation-based selective data sampling, designed with cross-operation analysis in mind,

* interactive outlier removal, at the measurement or part level, and a

* streamlined user interface, including single-click access to common tools and features.

“Selective data sampling and enhanced, multi-threaded data loading and manipulation provide customers with fast, efficient forms of single- and multiple-operation analysis,” continued Griffith. “Slicing and dicing large datasets has never been easier, because dataConductor 7.0 simplifies access to commonly used features such as editing limits and grouping data, helping reduce the time to make decisions.”

The dataConductor platform integrates a high-performance data warehouse with flexible analytics and reporting. Drag-and-drop, template-based analysis lets customers implement best practices, while Syntricity’s consulting services help companies recognize further yield improvements. Semiconductor companies of all sizes use dataConductor to analyze engineering data, ramp products to production, and manage and improve wafer and final test manufacturing yields.

“In dataConductor 7.0, our new user interface helps beginners and experts alike get more out of their analysis sessions. And now, customers can easily take best practices that they’ve implemented and turn them into standardized templates for their engineers, providing a solid foundation for various types of analysis,” said Steven Griffith, CEO and co-founder of Syntricity. “With dataConductor 7.0, we continue to deliver solutions that help our customers develop the next generation of semiconductor products.”

Highlights of dataConductor 7.0 include:

* knowledge sharing through user-configured/shareable templates,

* multi-threaded data loading and statistical analysis,

* new analysis capabilities in RaCR, the rapid characterization and root cause analysis application for dataConductor,

* operation-based selective data sampling, designed with cross-operation analysis in mind,

* interactive outlier removal, at the measurement or part level, and a

* streamlined user interface, including single-click access to common tools and features.

“Selective data sampling and enhanced, multi-threaded data loading and manipulation provide customers with fast, efficient forms of single- and multiple-operation analysis,” continued Griffith. “Slicing and dicing large datasets has never been easier, because dataConductor 7.0 simplifies access to commonly used features such as editing limits and grouping data, helping reduce the time to make decisions.”

The dataConductor platform integrates a high-performance data warehouse with flexible analytics and reporting. Drag-and-drop, template-based analysis lets customers implement best practices, while Syntricity’s consulting services help companies recognize further yield improvements. Semiconductor companies of all sizes use dataConductor to analyze engineering data, ramp products to production, and manage and improve wafer and final test manufacturing yields.

Electronics supply chain to fully recover from Japan disaster in Q3

EL SEGUNDO, USA: With some companies having already recovered from the Japanese earthquake, the entire electronics industry is expected to complete its rebound from the disaster by the end of the third quarter, according to new IHS iSuppli research.

Electronics companies with operations near the epicenter of the quake that had suffered building and equipment damage are expected to restore full shipments by early September, six months after the quake, which occurred on March 11, 2011. The restoration will coincide with the peak season for electronics and semiconductor sales in the third quarter.

“In the history of the electronics supply chain, nothing has had such a broad impact as the Japan earthquake, tsunami and nuclear disaster,” said Dale Ford, senior vice president for semiconductor market intelligence at IHS, speaking at the IHS Design & Supply Chain Global Summit last week in San Jose, Calif.

“The worldwide repercussions of the catastrophe illustrated the global and interconnected nature of the electronics industry, with the impact of the disaster reverberating through the materials, components and equipment segments of the supply chain. However, even the semiconductor companies suffering the most direct damage from the quake, full production will resume near the end of the third quarter.”

The duration of production disruptions varied depending on distance from the earthquake epicenter. Affected companies that were farthest from the epicenter took only one to two weeks to restore production, while companies closest to the disaster could take as long as four to six months to return to normal—depending on their response to the disaster. Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.

IHS has identified 14 semiconductor suppliers and four silicon wafer makers in Japan that were impacted by the quake.

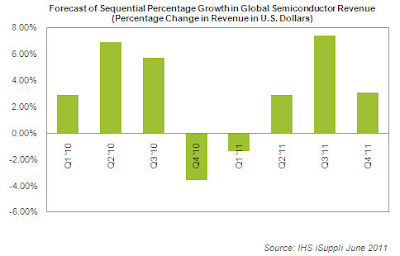

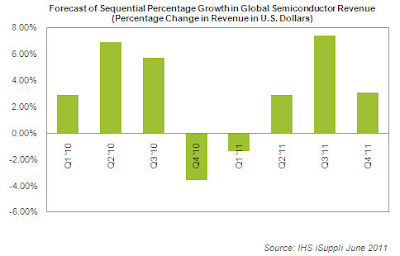

The timing of the recovery will be fortuitous. Following normal seasonal patterns, global semiconductor revenue growth will hit an annual crescendo in the third quarter, with a sequential rise of 7.4 percent. This compares to a 1.4 percent decline in the first quarter, a 2.9 percent increase in the second quarter and a 3.1 percent rise in the fourth quarter.

The disaster also had varying impacts on assorted segments of the semiconductor market. The impact was most severe on automotive equipment, given that Japan accounts for 31.5 percent of global semiconductor production for automotive electronics. Consumer electronics bore the next greatest impact, with a moderate effect on production. Here, Japan is responsible for 45.1 percent of global consumer electronics semiconductor production.

In comparison, the impact on the wireless and data processing semiconductor markets was mild, while the wired communications segment wasn’t affected at all. Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.

Post-disaster recovery for Fujitsu

The impact on specific companies also varied according to their level of exposure to the catastrophe and the effectiveness of their disaster-response efforts.

Fujitsu has distinguished itself with the most rapid and efficient recovery effort among all Japanese semiconductor suppliers, Ford said. Despite facilities close to the epicenter of the earthquake, the company said it had attained full recovery to pre-disaster production levels at five chip plants on June 9.

The main factor propelling Fujitsu’s fast recovery was the company’s disaster-response strategy implemented three years ago following an earthquake in Japan’s Iwate prefecture. The company operates semiconductor manufacturing facilities in various parts of the world, allowing it to pick up the slack if one region is hit by a disaster. Fujitsu also has an effective plan that can restore electricity, water and other utilities at disaster-stricken plants.

Furthermore, the company in the past had installed equipment that could seismically isolate damage to semiconductor wafers, which succeeded this time in mitigating the impact of the earthquake.

Source: IHS iSuppli, USA.

Electronics companies with operations near the epicenter of the quake that had suffered building and equipment damage are expected to restore full shipments by early September, six months after the quake, which occurred on March 11, 2011. The restoration will coincide with the peak season for electronics and semiconductor sales in the third quarter.

“In the history of the electronics supply chain, nothing has had such a broad impact as the Japan earthquake, tsunami and nuclear disaster,” said Dale Ford, senior vice president for semiconductor market intelligence at IHS, speaking at the IHS Design & Supply Chain Global Summit last week in San Jose, Calif.

“The worldwide repercussions of the catastrophe illustrated the global and interconnected nature of the electronics industry, with the impact of the disaster reverberating through the materials, components and equipment segments of the supply chain. However, even the semiconductor companies suffering the most direct damage from the quake, full production will resume near the end of the third quarter.”

The duration of production disruptions varied depending on distance from the earthquake epicenter. Affected companies that were farthest from the epicenter took only one to two weeks to restore production, while companies closest to the disaster could take as long as four to six months to return to normal—depending on their response to the disaster.

Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.IHS has identified 14 semiconductor suppliers and four silicon wafer makers in Japan that were impacted by the quake.

The timing of the recovery will be fortuitous. Following normal seasonal patterns, global semiconductor revenue growth will hit an annual crescendo in the third quarter, with a sequential rise of 7.4 percent. This compares to a 1.4 percent decline in the first quarter, a 2.9 percent increase in the second quarter and a 3.1 percent rise in the fourth quarter.

The disaster also had varying impacts on assorted segments of the semiconductor market. The impact was most severe on automotive equipment, given that Japan accounts for 31.5 percent of global semiconductor production for automotive electronics. Consumer electronics bore the next greatest impact, with a moderate effect on production. Here, Japan is responsible for 45.1 percent of global consumer electronics semiconductor production.

In comparison, the impact on the wireless and data processing semiconductor markets was mild, while the wired communications segment wasn’t affected at all.

Source: IHS iSuppli, USA.

Source: IHS iSuppli, USA.Post-disaster recovery for Fujitsu

The impact on specific companies also varied according to their level of exposure to the catastrophe and the effectiveness of their disaster-response efforts.

Fujitsu has distinguished itself with the most rapid and efficient recovery effort among all Japanese semiconductor suppliers, Ford said. Despite facilities close to the epicenter of the earthquake, the company said it had attained full recovery to pre-disaster production levels at five chip plants on June 9.

The main factor propelling Fujitsu’s fast recovery was the company’s disaster-response strategy implemented three years ago following an earthquake in Japan’s Iwate prefecture. The company operates semiconductor manufacturing facilities in various parts of the world, allowing it to pick up the slack if one region is hit by a disaster. Fujitsu also has an effective plan that can restore electricity, water and other utilities at disaster-stricken plants.

Furthermore, the company in the past had installed equipment that could seismically isolate damage to semiconductor wafers, which succeeded this time in mitigating the impact of the earthquake.

Source: IHS iSuppli, USA.

ScaleMP ranks among fastest worldwide on SPEC benchmarks

CUPERTINO, USA: ScaleMP, a leading provider of virtualization solutions for high-end computing, has announced record-breaking benchmark results for x86 systems using the company’s vSMP Foundation software. vSMP Foundation claimed top three results for two Standard Performance Evaluation Corporation (SPEC) benchmarks, representing the highest performance in cloud-enabled x86 shared memory systems.

vSMP Foundation enables customers to create shared-memory systems from their cloud-enabled datacenters, providing applications with large memory and shared memory for the lowest TCO. This solution provides the most power-efficient SMP system, leveraging commercial off-the-shelf (COTS) hardware. The on-demand nature of vSMP Foundation improves system utilization and reduces management complexity.

ScaleMP benchmarking experts used 64 dual-socket nodes, aggregated into a single virtual shared-memory system to gain the record-breaking results for SPECint_rate_base2006, which achieved 13,600, receiving top three status for this benchmark and solidifying ScaleMP’s leadership in powering high-end x86 systems.

"vSMP Foundation’s outstanding results from its single, virtual solution aggregating multiple, industry-standard x86 machines proves once again its superior performance and cost savings for customers seeking a powerful and affordable shared-memory system," said Shai Fultheim, founder and CEO of ScaleMP.

vSMP Foundation enables customers to create shared-memory systems from their cloud-enabled datacenters, providing applications with large memory and shared memory for the lowest TCO. This solution provides the most power-efficient SMP system, leveraging commercial off-the-shelf (COTS) hardware. The on-demand nature of vSMP Foundation improves system utilization and reduces management complexity.

ScaleMP benchmarking experts used 64 dual-socket nodes, aggregated into a single virtual shared-memory system to gain the record-breaking results for SPECint_rate_base2006, which achieved 13,600, receiving top three status for this benchmark and solidifying ScaleMP’s leadership in powering high-end x86 systems.

"vSMP Foundation’s outstanding results from its single, virtual solution aggregating multiple, industry-standard x86 machines proves once again its superior performance and cost savings for customers seeking a powerful and affordable shared-memory system," said Shai Fultheim, founder and CEO of ScaleMP.

Rite Track partners with Aviza to liquidate parts inventory in Europe and Asia

WEST CHESTER, USA: Rite Track Inc., a leading semiconductor equipment supplier announced a partnership with ATI Liquidating Inc. (ATI), formerly Aviza Technology Inc. to assist in the liquidation of ATI’s remaining inventory in Europe and Asia. The deal leverages Rite Track’s strong global logistics network to provide ATI Thermal, Etch and PVD customers in Europe and Asia quick access to available ATI parts currently under liquidation.

ATI CRO, Pat O’Connor stated: “Rite Track’s strong logistics network and commitment to quality parts support was a key driver in the decision to move forward with this arrangement. Rite Track is well positioned globally and their existing customer base aligns well with our install base to strengthen our parts liquidation program.”

As a part of the agreement, inventory will be moved from current locations in Europe and Asia to regional Rite Track distribution centers in Asia, Japan, and Europe. Once the inventory is relocated, customers can order available parts directly from Rite Track’s regional offices.

ATI CRO, Pat O’Connor stated: “Rite Track’s strong logistics network and commitment to quality parts support was a key driver in the decision to move forward with this arrangement. Rite Track is well positioned globally and their existing customer base aligns well with our install base to strengthen our parts liquidation program.”

As a part of the agreement, inventory will be moved from current locations in Europe and Asia to regional Rite Track distribution centers in Asia, Japan, and Europe. Once the inventory is relocated, customers can order available parts directly from Rite Track’s regional offices.

Analog Devices’ MEMS iSensor digital inclinometer system delivers 0.1-degree roll/pitch accuracy with simple set up

NORWOOD, USA: Analog Devices Inc. (ADI), released for general availability today the ADIS16210 MEMS iSensor digital inclinometer system, which provides precise measurements for both pitch and roll angles over a full orientation range of ±180 degrees.

The ADIS16210 integrates ADI’s iMEMS multi-axis accelerometer technology and signal processing expertise, adding addressable user registers for application tuning and programming, available over an SPI-compatible serial interface. The precision core sensors are tuned to allow accurate roll/pitch outputs independent of the orientation of the mounted sensor.

The ADIS16210 eliminates complex and time consuming user calibration with unit-specific factory calibration, delivering extraordinary 0.1-degree tilt accuracy out of the box. Designed for the most demanding applications, the ADIS16210 is optimized for instruments such as medical scanners that require highly accurate platform stabilization, security and safety monitors, and high-precision platform positioning/steering.

For applications where motion is experienced on every axis and in extreme environments, multi-axis sensing and precision sensor processing is critical. Each ADIS16210 receives extensive calibration and testing to insure a high degree of alignment across each of the three axes and unprecedented tilt measurement accuracy over the full motion range, independent of mounting orientation.

This new digital inclinometer system also offers digital accelerometer and temperature sensor measurements together with configuration controls for in-system calibration, sample rate, filtering, alarms, I/O configuration, and power management. The ADIS16210 is available in a 15×2×15mm module that provides mounting tabs with M2-sized mounting holes and a flexible, edge-terminated connector interface. It has an extended operating temperature range of −40 °C to +125 °C.

The ADIS16210 integrates ADI’s iMEMS multi-axis accelerometer technology and signal processing expertise, adding addressable user registers for application tuning and programming, available over an SPI-compatible serial interface. The precision core sensors are tuned to allow accurate roll/pitch outputs independent of the orientation of the mounted sensor.

The ADIS16210 eliminates complex and time consuming user calibration with unit-specific factory calibration, delivering extraordinary 0.1-degree tilt accuracy out of the box. Designed for the most demanding applications, the ADIS16210 is optimized for instruments such as medical scanners that require highly accurate platform stabilization, security and safety monitors, and high-precision platform positioning/steering.

For applications where motion is experienced on every axis and in extreme environments, multi-axis sensing and precision sensor processing is critical. Each ADIS16210 receives extensive calibration and testing to insure a high degree of alignment across each of the three axes and unprecedented tilt measurement accuracy over the full motion range, independent of mounting orientation.

This new digital inclinometer system also offers digital accelerometer and temperature sensor measurements together with configuration controls for in-system calibration, sample rate, filtering, alarms, I/O configuration, and power management. The ADIS16210 is available in a 15×2×15mm module that provides mounting tabs with M2-sized mounting holes and a flexible, edge-terminated connector interface. It has an extended operating temperature range of −40 °C to +125 °C.

SMSC licenses Cosmic Circuits IP

BANGALORE, INDIA & CAMPBELL, USA: Cosmic Circuits, a leading provider of Analog and Mixed-Signal Silicon IP Cores announced that SMSC, a leading semiconductor company enabling content rich connectivity systems, has licensed Cosmic Circuits IP for use in its product development.

Cosmic Circuits offers a broad portfolio of differentiated Analog IP cores in nanometer technology nodes covering Data-Converters, Analog-Front-End platforms for Wireless and Audio, Power-Management, Clocking and MIPI Interfaces.

Cosmic Circuits has a portfolio of more than 300+ cores covering process technologies from 0.18u to 28nm. Cosmic Circuits power management portfolio consists of DC/DC Buck, DC/DC Boost, DC/DC Buck Boost, Low Drop out regulators, Power–On-Reset, Capacitive charge pumps, USB battery chargers and High precision band-gap references.

Ganapathy Subramaniam, CEO of Cosmic Circuits, commented: “We are very happy to enable SMSC with our solutions to meet their aggressive design requirements. SMSC’s specification called for stringent requirements on leakage current as well as high-voltage tolerance. Using design techniques that we have perfected at Cosmic over several successful implementations, we were able to meet the system requirements on the first-pass silicon in a standard CMOS process.”

Hemi Bhatnagar, VP of Engineering at SMSC added: “We needed a partner who had a proven track record in providing Analog/Mixed Signal solutions with a wide-portfolio and a willingness to customize to our needs. Cosmic Circuits along with strong technical expertise provided strong support and excellent project execution resulting in first pass working silicon.”

Cosmic Circuits offers a broad portfolio of differentiated Analog IP cores in nanometer technology nodes covering Data-Converters, Analog-Front-End platforms for Wireless and Audio, Power-Management, Clocking and MIPI Interfaces.

Cosmic Circuits has a portfolio of more than 300+ cores covering process technologies from 0.18u to 28nm. Cosmic Circuits power management portfolio consists of DC/DC Buck, DC/DC Boost, DC/DC Buck Boost, Low Drop out regulators, Power–On-Reset, Capacitive charge pumps, USB battery chargers and High precision band-gap references.

Ganapathy Subramaniam, CEO of Cosmic Circuits, commented: “We are very happy to enable SMSC with our solutions to meet their aggressive design requirements. SMSC’s specification called for stringent requirements on leakage current as well as high-voltage tolerance. Using design techniques that we have perfected at Cosmic over several successful implementations, we were able to meet the system requirements on the first-pass silicon in a standard CMOS process.”

Hemi Bhatnagar, VP of Engineering at SMSC added: “We needed a partner who had a proven track record in providing Analog/Mixed Signal solutions with a wide-portfolio and a willingness to customize to our needs. Cosmic Circuits along with strong technical expertise provided strong support and excellent project execution resulting in first pass working silicon.”

Applied Materials reveals breakthrough RTP technology for 20nm era

SANTA CLARA, USA: Applied Materials Inc. advanced the state of the art in nanoscale transistor fabrication with the launch of its Applied Vantage Vulcan rapid thermal processing (RTP) system. The system leapfrogs current RTP technology to bring a new level of precision and control to the anneal process, enabling chipmakers to reduce variability and boost production yields of their most highly-valued, highest-performing devices.

For manufacturers to achieve the highest chip yields, transistors with the same design should perform identically in all areas of the wafer. This is becoming a major challenge at the 20nm era (28nm and below) since transistors are smaller and more sensitive to temperature variations while many logic chips are also larger in size, making uniformity across the die increasingly difficult. Direct radiant heating can cause variations in temperature, or "hot spots," on a patterned wafer - leading to significant variations in the electrical performance of the transistors - and resulting in many low-end chips on the wafer.

Applied's Vantage Vulcan system overcomes these yield-limiting temperature variations by applying heat to the unpatterned backside of the wafer to deliver an unprecedented level of temperature uniformity. Using the company's proven honeycomb lamp array, the system can control within-die temperature to less than 3°C - even while the wafer temperature is aggressively ramping at more than 200°C per second.

"The Vantage Vulcan system represents a significant technology extension for the industry's roadmap and sets a new benchmark in eliminating sources of temperature variability," said Sundar Ramamurthy, VP and GM of Applied Materials' Front End Products business unit. "We've listened to the needs of our customers and developed a solution that addresses one of their most daunting challenges. Leading chip manufacturers are already recognizing the device benefits of our new Vantage Vulcan system."

In addition to being the first RTP system to heat the wafer entirely from the backside, the Vantage Vulcan system's unique closed-loop control can dynamically control wafer temperature as it ramps from almost room temperature to 1,300°C. This breakthrough capability enables any device wafer, including wafers with challenging reflective surfaces, to be processed without recipe modification - a critical benefit for the high-mix, fast-changing environment of foundries - while also simplifying the integration of new materials and new transistor architectures.

Applied's expertise in temperature control has made the company both a pioneer and market leader in RTP technology. Applied has more than 1,000 RTP systems installed at customers worldwide, making Applied's RTP technology the industry's choice for manufacturing nearly every advanced microchip in the last decade.

For manufacturers to achieve the highest chip yields, transistors with the same design should perform identically in all areas of the wafer. This is becoming a major challenge at the 20nm era (28nm and below) since transistors are smaller and more sensitive to temperature variations while many logic chips are also larger in size, making uniformity across the die increasingly difficult. Direct radiant heating can cause variations in temperature, or "hot spots," on a patterned wafer - leading to significant variations in the electrical performance of the transistors - and resulting in many low-end chips on the wafer.

Applied's Vantage Vulcan system overcomes these yield-limiting temperature variations by applying heat to the unpatterned backside of the wafer to deliver an unprecedented level of temperature uniformity. Using the company's proven honeycomb lamp array, the system can control within-die temperature to less than 3°C - even while the wafer temperature is aggressively ramping at more than 200°C per second.

"The Vantage Vulcan system represents a significant technology extension for the industry's roadmap and sets a new benchmark in eliminating sources of temperature variability," said Sundar Ramamurthy, VP and GM of Applied Materials' Front End Products business unit. "We've listened to the needs of our customers and developed a solution that addresses one of their most daunting challenges. Leading chip manufacturers are already recognizing the device benefits of our new Vantage Vulcan system."

In addition to being the first RTP system to heat the wafer entirely from the backside, the Vantage Vulcan system's unique closed-loop control can dynamically control wafer temperature as it ramps from almost room temperature to 1,300°C. This breakthrough capability enables any device wafer, including wafers with challenging reflective surfaces, to be processed without recipe modification - a critical benefit for the high-mix, fast-changing environment of foundries - while also simplifying the integration of new materials and new transistor architectures.

Applied's expertise in temperature control has made the company both a pioneer and market leader in RTP technology. Applied has more than 1,000 RTP systems installed at customers worldwide, making Applied's RTP technology the industry's choice for manufacturing nearly every advanced microchip in the last decade.

IDT intros industry’s widest-range, small-footprint spread spectrum clock generators

SAN JOSE, USA: Integrated Device Technology Inc. (IDT) announced that it has released a new family of low-power spread spectrum clock generators that support the industry’s widest frequency range in a tiny 2x2mm package. The wide frequency range and compact package make the device highly versatile and unobtrusive, allowing users to address EMI challenges in a variety of applications including digital TVs, set-top boxes, printers, industrial control, battery powered electronics, and computer or embedded computing systems.

The IDT 5P5090x family of devices support spread spectrum clocking frequencies from 10MHz to 170MHz with seven selectable modulation amplitudes and operate with a supply voltage down to 1.8V for reduced power consumption. The device is available in a low-cost, minuscule 2x2mm 8-pin DFN or MSOP package, minimizing the board area required for placement, a critical requirement for today’s compact consumer products.

The wide frequency range and small package make it a smart choice for new designs as a preventative measure against excessive EMI output and also convenient for existing designs as an indispensable solution when EMI tests have failed to meet stringent requirements – all without sacrificing valuable board space.

“Our latest spread spectrum clock generators reinforce IDT’s #1 leadership position in clocks and timing solutions,” said Ram Iyer, vice president and general manager of the Computing and Multimedia Division at IDT. “The wide frequency range, selectable modulation amplitudes, and small package are exactly what our customers have been asking for. In addition, we’ve lowered the power consumption to offer one of the industry’s most efficient products. EMI can be a simple problem to solve with the right products, and IDT’s rich portfolio contains devices aimed at addressing EMI challenges.”

The IDT 5P5090x family is the next generation of IDT’s leading MK17xx family devices. The lower power consumption (1.8V supply) and smaller package (2x2mm) make this an obvious upgrade path for new designs. These products are one of thousands of IDT world-class timing products, and complement IDT’s broad portfolio of products for consumer and computing applications where EMI compliance is critical.

The IDT 5P5090x family of products is currently sampling to qualified customers and the devices are available in a 2x2mm DFN or MSOP package. The IDT 5P5090x is priced at $0.87 each for volumes of 10,000 units.

The IDT 5P5090x family of devices support spread spectrum clocking frequencies from 10MHz to 170MHz with seven selectable modulation amplitudes and operate with a supply voltage down to 1.8V for reduced power consumption. The device is available in a low-cost, minuscule 2x2mm 8-pin DFN or MSOP package, minimizing the board area required for placement, a critical requirement for today’s compact consumer products.

The wide frequency range and small package make it a smart choice for new designs as a preventative measure against excessive EMI output and also convenient for existing designs as an indispensable solution when EMI tests have failed to meet stringent requirements – all without sacrificing valuable board space.

“Our latest spread spectrum clock generators reinforce IDT’s #1 leadership position in clocks and timing solutions,” said Ram Iyer, vice president and general manager of the Computing and Multimedia Division at IDT. “The wide frequency range, selectable modulation amplitudes, and small package are exactly what our customers have been asking for. In addition, we’ve lowered the power consumption to offer one of the industry’s most efficient products. EMI can be a simple problem to solve with the right products, and IDT’s rich portfolio contains devices aimed at addressing EMI challenges.”

The IDT 5P5090x family is the next generation of IDT’s leading MK17xx family devices. The lower power consumption (1.8V supply) and smaller package (2x2mm) make this an obvious upgrade path for new designs. These products are one of thousands of IDT world-class timing products, and complement IDT’s broad portfolio of products for consumer and computing applications where EMI compliance is critical.

The IDT 5P5090x family of products is currently sampling to qualified customers and the devices are available in a 2x2mm DFN or MSOP package. The IDT 5P5090x is priced at $0.87 each for volumes of 10,000 units.

NI intros industry’s highest throughput PXI frame grabber

USA: National Instruments announced the NI PXIe-1435 high-performance Camera Link frame grabber. Engineers can use the new module to integrate high-speed and high-resolution imaging into their PXI systems, the industry standard for automated test with more than 1,500 measurement modules available from more than 70 vendors.

By combining high-throughput imaging with the benefits of off-the-shelf PXI measurement hardware, NI now offers full software-defined solutions for demanding automated test applications in industries such as consumer electronics, automotive and semiconductor.

The NI PXIe-1435 is the industry’s highest throughput PXI frame grabber and acquires from all Camera Link camera configurations, including 10-tap extended-full, with up to 850 MB/s of throughput. Engineers can power cameras through Power over Camera Link (PoCL)-enabled cables, eliminating the need for additional wires in deployment environments.

The frame grabber also offers 512 MB of DDR2 onboard acquisition memory for added reliability in transferring large images without fear of data overflow. Onboard digital I/O includes four bidirectional transistor-transistor logic (TTL), two opto-isolated inputs and one quadrature encoder for triggering and communicating inspection results with automation devices.

The frame grabber incorporates the synchronization, timing, data streaming and processing capabilities of the PXI Express specification, and supports image processing on complementary field-programmable gate array (FPGA) boards to further boost system performance.

“The NI PXIe-1435 frame grabber further complements our capabilities in the PXI platform,” said Matt Friedman, National Instruments senior product manager for the PXI platform and PXISA board member. “The addition of high-performance imaging to our PXI offerings enhances our mixed-signal capabilities for high-end test systems.”

The high throughput and low latency of the Camera Link standard make the frame grabber ideal for line-scan image sensors, which engineers can use for surface inspection of large areas, including finding esthetic and functional defects in solar panels and dead pixels in flat panel displays.

The NI PXIe-1435 frame grabber also works well in many industrial applications, such as fault analysis using a stop trigger to record images before and after an event on the factory floor, and medical device applications such as analyzing intricacies in movement and recording stimulus response in objects from heart valves to eye corneas.

Engineers can program the new module using NI LabVIEW graphical development software and the NI Vision Development Module, a comprehensive library of imaging functions. They also can configure it using NI Vision Builder for Automated Inspection software, an easy-to-use, stand-alone package for fast development and simple maintenance.

NI vision software helps engineers take advantage of hundreds of imaging processing algorithms, make decisions based on multiple inspection results, customize user interfaces and communicate results using I/O and industrial communication protocols.

By combining high-throughput imaging with the benefits of off-the-shelf PXI measurement hardware, NI now offers full software-defined solutions for demanding automated test applications in industries such as consumer electronics, automotive and semiconductor.

The NI PXIe-1435 is the industry’s highest throughput PXI frame grabber and acquires from all Camera Link camera configurations, including 10-tap extended-full, with up to 850 MB/s of throughput. Engineers can power cameras through Power over Camera Link (PoCL)-enabled cables, eliminating the need for additional wires in deployment environments.

The frame grabber also offers 512 MB of DDR2 onboard acquisition memory for added reliability in transferring large images without fear of data overflow. Onboard digital I/O includes four bidirectional transistor-transistor logic (TTL), two opto-isolated inputs and one quadrature encoder for triggering and communicating inspection results with automation devices.

The frame grabber incorporates the synchronization, timing, data streaming and processing capabilities of the PXI Express specification, and supports image processing on complementary field-programmable gate array (FPGA) boards to further boost system performance.

“The NI PXIe-1435 frame grabber further complements our capabilities in the PXI platform,” said Matt Friedman, National Instruments senior product manager for the PXI platform and PXISA board member. “The addition of high-performance imaging to our PXI offerings enhances our mixed-signal capabilities for high-end test systems.”

The high throughput and low latency of the Camera Link standard make the frame grabber ideal for line-scan image sensors, which engineers can use for surface inspection of large areas, including finding esthetic and functional defects in solar panels and dead pixels in flat panel displays.

The NI PXIe-1435 frame grabber also works well in many industrial applications, such as fault analysis using a stop trigger to record images before and after an event on the factory floor, and medical device applications such as analyzing intricacies in movement and recording stimulus response in objects from heart valves to eye corneas.

Engineers can program the new module using NI LabVIEW graphical development software and the NI Vision Development Module, a comprehensive library of imaging functions. They also can configure it using NI Vision Builder for Automated Inspection software, an easy-to-use, stand-alone package for fast development and simple maintenance.

NI vision software helps engineers take advantage of hundreds of imaging processing algorithms, make decisions based on multiple inspection results, customize user interfaces and communicate results using I/O and industrial communication protocols.

Emerson Network Power showcases industry’s latest COM Express

SAN ANTONIO, USA: Attendees of the Freescale Technology Forum Americas 2011 this week can see the latest COM Express embedded computing modules powered by Freescale Semiconductor QorIQ processors. Emerson Network Power, a business of Emerson and the global leader in enabling Business-Critical Continuity, is announcing the COMX-P3041, COMX-P4040 and COMX-P5020 modules at this renowned industry event.

These new products can speed deployment for users of QorIQ processors with diverse I/O requirements by reducing design complexity while providing customizable modular options. Design engineers are isolated from the complexities of high speed processor and memory system design, allowing them to focus on a carrier board tailored to the I/O needs of their application and improving their product to gain market share.

Applications for Emerson's QorIQ COM Express modules include enterprise and service provider routers, switches, base station controllers (BSCs), radio network controllers (RNCs), long-term evolution (LTE) infrastructure and general-purpose embedded computing systems in the networking, telecom/datacom, wireless infrastructure, industrial, military and aerospace markets.

Glenn Beck, marketing manager with Freescale’s Networking Processor Division, said: “The COMX-Pxxx modules from Emerson Network Power provide the performance and features of the Freescale QorIQ processors on a ready-to-go pluggable mezzanine

module. These modules are designed to accelerate time-to-market by reducing design and development complexities, while simultaneously maximizing product performance, which continues to be a critical operational theme for OEMs and systems integrators. The long standing relationship between Emerson Network Power and Freescale has created a comprehensive breadth of price, power and performance for the QorIQ family on the COM Express form factor, providing OEMs outstanding embedded solutions based on Power Architecture technology.”